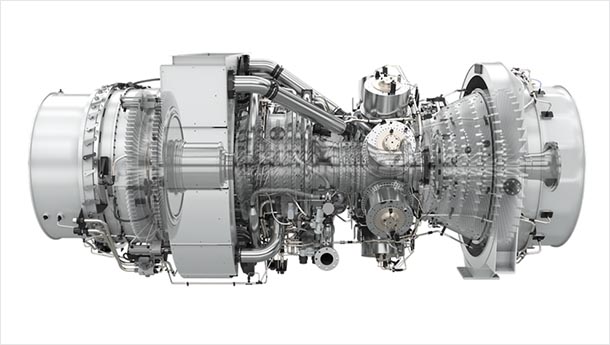

The U.S. Department of Energy has funded three projects in the Penn State Department of Mechanical Engineering in order to improve gas turbines for advanced energy production. IMAGE: PENN STATE

Penn State awarded $3.3M to develop more efficient gas turbines

Three projects selected by the U.S. Department of Energy to help develop near-zero-emission advanced turbine technologies

11/8/2019

By Erin Cassidy Hendrick

UNIVERSITY PARK, Pa. — Researchers in the Penn State Department of Mechanical Engineering have been awarded more than a combined $3.3 million to support advancements in the performance and efficiency of combustion turbines and turbine-based power cycles in fossil fuel power generation.

The U.S. Department of Energy has funded these projects through the University Turbine Systems Research program, which aims to lessen the environmental concerns associated with fossil fuels by developing revolutionary, near-zero-emission advanced turbine technologies. Nationwide, seven projects were selected for the program, three of which are powered by Penn State research.

As a historical leader in gas turbines, the University is poised to forge new knowledge by harnessing the power and potential of additive manufacturing.

Stephen Lynch, the Shuman Family Early Career Professor and associate professor of mechanical engineering, will spearhead a project to develop new insights into how additive manufacturing can enable transformative levels of performance for ceramic matrix composite turbine vanes, components that are subjected to some of the highest temperatures in the engine. His project has been awarded $1.1 million. Lynch will collaborate with Michael Hickner, professor of materials science and engineering and chemical engineering at Penn State, as well as a team of researchers from the University of Wyoming.

Karen Thole, distinguished professor, mechanical engineering department head and director of the Steady Thermal Aero Research Turbine lab, will collaborate with researchers from the University of Texas at Austin to use additive manufacturing technology for improved cooling effectiveness in turbine components, particularly vanes and blades. By taking a holistic stance on cooling, the research aims to explore how the synergy of independent cooling mechanisms can be combined for improved performance. This project has received $1.1 million in DOE funding.

Jacqueline O’Connor, associate professor of mechanical engineering, Guha Manogharan, assistant professor of mechanical engineering and industrial and manufacturing engineering, and Yuan Xuan, assistant professor of mechanical engineering, have been awarded $1.1 million for their project. Their work will use additive manufacturing techniques to radically re-imagine the design and manufacturing of fuel injection hardware for power generation gas turbines.

Together, these projects will help support improved turbine efficiency to both increase cost savings and lessen environmental impacts.

“In the Department of Mechanical Engineering, we are excited to contribute to the DOE’s mission for improving gas turbines in energy production,” Thole said. “Our goal is to ensure our new methods are directly applicable to industry and guide new pathways for fuel efficiency nationwide.”